Improved External Cooling

With competing continuous spray systems that use water-based lubricants, die casters often experience poor external cooling effects and subpar lubricant adhesion. Water evaporates upon contact with the high-temperature die, forming a gas that acts as a barrier between die lubricant and the mold. This barrier of evaporated water prevents lubricant adhesion and is known as the Leidenfrost effect. The surface temperature of the mold must gradually converge with the Leidenfrost point 193 °C (379 °F) before lubricant can finally adhere. Such drastic heating and cooling takes time, and can cause damage to the die over repeated cycles. Significant quantities of water-based lubricant are used to cool the die before finally forming lubricant film, resulting in a large quantity of waste.

With EcoShot's rapid pulse spray, external cooling effects are improved through mitigation of the Leidenfrost effect. Though rapid pulsing of lubricant spray, water is allowed to fully evaporate before applying additional lubricant, which prevents a gaseous barrier from forming. As the barrier is not able to form, EcoShot's pulse spray improves lubricant adhesion, even at higher die temperatures. With this rapidly repeated process of spraying and evaporation, external die cooling becomes faster and requires less die lubricant. Cycle time decreases due to the unprecedented 0.01 second pulsations and lubricant quantity is drastically reduced.

EcoShot Nozzle

Achieve unprecedented pulse speed with our solenoid nozzle

離型剤使用量を削減

-

油性・水溶性原液を効率良く、均一に塗布

-

水溶性希釈液は高効率での脱熱効果、高温部のみへの集中的な塗布

-

離型剤使用量の減少によるコスト削減

サイクルタイムを短縮

-

シミュレーションにより最適化されたノズル配置、RB動作によるサイクル短縮

-

必要最低限の塗布による液伸ばしブローの短縮

環境への配慮、カーボンニュートラルへ対応

-

過剰な塗布がなくなるため、大量の廃液処理から解放

-

大気中に拡散される離型剤量も低減され、作業環境が向上

Benefit Overview

従来品との比較検証

Need concrete data? We have conducted an experiment to see how spray patterns affect die temperature lubricant quantity. With Ecoshot's pulse spray, the amount of lubricant usage and wastewater is significantly reduced, and improved die cooling is observed.

A

B

A

B

A

B

A

B

Before Spraying

Continuous Spray

EcoShot Pulse

EcoShot Rapid Pulse

Temperature

A… 309.88 ℃

B… 311.29 ℃

1 second after spraying

A… 261.99 ℃

B… 272.01 ℃

1 second after spraying

A… 253.34 ℃

B… 273.73 ℃

1 second after spraying

A… 232.23 ℃

B… 253.93 ℃

Cycle Time

3.5 sec.

3.5 sec.

3.5 sec.

Spray Pattern

Spray... 3.5 sec.

Stop... None

Spray... 0.5 sec. X 4 times

Stop... 0.5 sec. X 3 times

Spray... 0.25 sec. X 7 times

Stop... 0.25 sec. X 7 times

Lubricant Quantity

42cc

24cc

21cc

Observations

Significant dripping and wastewater. Poor lubricant adhesion due to Leidenfrost effect.

Improved adhesion (via mitigation of Leidenfrost effect) and reduction in wastewater. Improved cooling in certain areas.

Improved adhesion (via mitigation of Leidenfrost effect) and reduction in wastewater. Significantly improved cooling.

Results

Adhesion ... Poor

Wastewater ... Significant

Vaporization ... Small

Adhesion ... Good

Wastewater... Low

Vaporization ... High

Adhesion ... Excellent

Wastewater ... None

Vaporization ... High

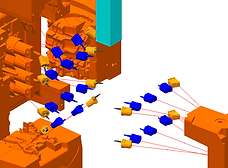

EcoShot Simulation

Simulate your spray patterns with Envision, for unparalleled control

-

Determine optimal nozzle arrangement and robotic movement

-

Test robotic movement and spray pattern before production

-

Know the cycle time in advance

-

Shortening on-site installation time

-

Plan for quality control before large-scale production

Optimize

Nozzle placement

Streamline Robotic Movement

Refine Spray

Pattern

Project and Improve

Cycle Time